How Important Are Feed Ramps Machined Into An AR-15 Upper Receiver?

The AR-15 platform has become ubiquitous in the firearms world, known for its modularity and adaptability. Among the many components that contribute to its reliability, the feed ramp, particularly those machined into the upper receiver, plays a crucial role. Understanding the importance of feed ramps in an AR-15 upper receiver is essential for any AR-15 owner or enthusiast. This article will delve into the function, benefits, and considerations surrounding feed ramps in AR-15 upper receivers.

What is a Feed Ramp?

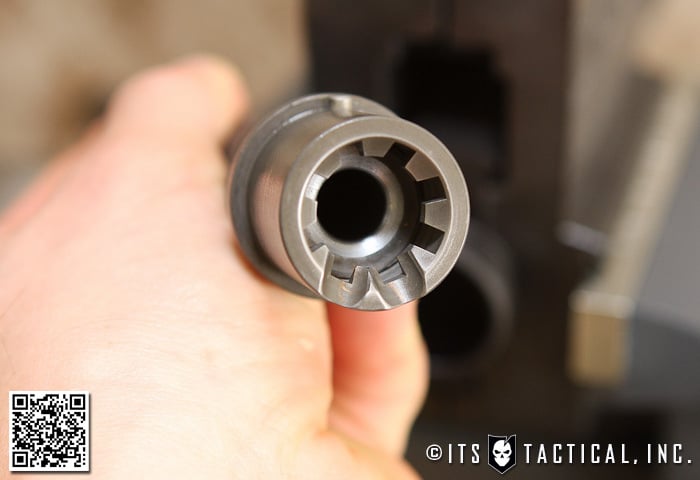

Before discussing the importance of feed ramps machined into an AR-15 upper receiver, it’s crucial to understand what they are and what purpose they serve. A feed ramp is a sloped surface designed to guide a cartridge from the magazine into the chamber of a firearm. In an AR-15, the feed ramp is typically found in two places: the barrel extension and, sometimes, the upper receiver itself.

The primary function of the feed ramp is to ensure a smooth and reliable feeding process. Without a properly designed and executed feed ramp, cartridges can jam, misfeed, or otherwise fail to enter the chamber correctly, leading to malfunctions and potentially dangerous situations.

The Role of Feed Ramps in AR-15 Upper Receivers

When discussing feed ramps machined into an AR-15 upper receiver, it’s important to distinguish between the two main types of feed ramp configurations: M4 feed ramps and standard feed ramps. M4 feed ramps are characterized by a wider and more gradual angle compared to standard feed ramps. These are specifically designed to improve feeding reliability, especially in shorter-barreled AR-15 variants often used in military applications.

The feed ramp machined into the upper receiver works in conjunction with the feed ramp on the barrel extension. When a cartridge is stripped from the magazine, it encounters the feed ramps as it moves forward. The ramps guide the bullet nose upwards and into the chamber, ensuring that the cartridge aligns correctly. The presence of M4 feed ramps in the upper receiver helps to create a more seamless transition, reducing the likelihood of the bullet nose catching on the edge of the chamber.

Why Are Feed Ramps Machined Into the Upper Receiver Important?

The importance of feed ramps machined into an AR-15 upper receiver stems from their ability to enhance the firearm’s reliability. Here are several key reasons why they are considered essential:

Improved Feeding Reliability

The primary benefit of having feed ramps machined into the upper receiver is improved feeding reliability. By providing a smoother and more consistent path for the cartridge to enter the chamber, these feed ramps reduce the chance of malfunctions. This is particularly important in high-stress situations where a reliable firearm is critical. The AR-15’s reputation for reliability is significantly bolstered by well-designed feed ramps.

Compatibility with Various Ammunition Types

Different types of ammunition can have varying bullet shapes and lengths. Some bullets may be more prone to catching or jamming during the feeding process. Feed ramps machined into the upper receiver can help accommodate a wider range of ammunition types, making the AR-15 more versatile. This is particularly relevant for shooters who use a variety of ammunition for different purposes, such as target shooting, hunting, or self-defense.

Enhanced Performance in Short-Barreled Rifles (SBRs)

Short-barreled rifles often have a more violent cycling action due to the shorter dwell time and increased gas pressure. This can exacerbate feeding issues. M4 feed ramps are specifically designed to address these challenges by providing a more forgiving feeding path. Therefore, feed ramps machined into the upper receiver are particularly important for SBRs to ensure reliable operation.

Increased Lifespan of Components

A smooth and reliable feeding process reduces the stress on other components of the AR-15, such as the bolt, extractor, and magazine. By minimizing the force required to chamber a round, feed ramps machined into the upper receiver can help extend the lifespan of these parts. This can lead to cost savings over time, as well as improved overall performance.

Easier Troubleshooting

When diagnosing feeding issues in an AR-15, the feed ramps are often one of the first areas to inspect. If the feed ramps are properly machined and aligned, it can help rule out potential causes of malfunctions. This can make troubleshooting easier and more efficient, saving time and frustration. A well-machined feed ramp contributes to the overall ease of maintenance and repair of the AR-15.

Considerations When Choosing an Upper Receiver with Feed Ramps

When selecting an AR-15 upper receiver, there are several factors to consider regarding the feed ramps:

Material and Machining Quality

The material and machining quality of the upper receiver are crucial. The feed ramps should be precisely machined from high-quality materials, such as 7075-T6 aluminum, to ensure durability and reliability. Poorly machined feed ramps can be just as problematic as not having them at all. Look for reputable manufacturers known for their quality control and attention to detail.

Compatibility with the Barrel Extension

The feed ramps in the upper receiver must be compatible with the feed ramps on the barrel extension. Ideally, the two sets of feed ramps should align seamlessly to create a smooth and continuous feeding path. If the feed ramps are misaligned, it can lead to malfunctions. It is generally recommended to use a matched upper receiver and barrel extension from the same manufacturer to ensure proper compatibility.

M4 vs. Standard Feed Ramps

Decide whether you need M4 feed ramps or if standard feed ramps are sufficient for your needs. As mentioned earlier, M4 feed ramps are generally recommended for SBRs and firearms that will be used with a variety of ammunition types. Standard feed ramps may be adequate for longer-barreled rifles that will primarily be used with standard ammunition. Consider your specific application and choose accordingly.

Coating and Finish

The coating and finish of the upper receiver can also affect the performance of the feed ramps. A smooth and durable coating, such as Cerakote or anodizing, can help reduce friction and improve feeding reliability. Avoid upper receivers with coatings that are prone to chipping or flaking, as this can interfere with the feeding process.

Potential Issues and How to Address Them

Even with well-machined feed ramps, issues can still arise. Here are some common problems and how to address them:

Misalignment

If the feed ramps in the upper receiver and barrel extension are misaligned, it can cause malfunctions. This can sometimes be corrected by carefully filing or polishing the feed ramps to create a smoother transition. However, this should only be done by a qualified gunsmith, as improper modifications can damage the firearm. Using matched components from the same manufacturer is the best way to avoid misalignment issues.

Rough Surfaces

If the feed ramps have rough or uneven surfaces, it can impede the feeding process. This can be addressed by carefully polishing the feed ramps with a fine abrasive compound. Again, this should only be done by a qualified gunsmith to avoid damaging the firearm.

Damage

If the feed ramps are damaged, such as from being struck by a bullet or other object, it can cause malfunctions. In this case, the upper receiver or barrel extension may need to be replaced. It is important to inspect the feed ramps regularly for any signs of damage.

Conclusion

In conclusion, feed ramps machined into an AR-15 upper receiver are incredibly important for ensuring the reliability and performance of the firearm. By providing a smooth and consistent feeding path for cartridges, these feed ramps reduce the chance of malfunctions and improve the overall shooting experience. When choosing an upper receiver, it is essential to consider the material, machining quality, compatibility with the barrel extension, and coating of the feed ramps. Proper maintenance and inspection are also crucial for preventing and addressing potential issues. Understanding the significance of feed ramps is a key aspect of being a responsible and informed AR-15 owner. The presence of well-executed feed ramps is a testament to the quality and attention to detail in the manufacturing process, ultimately contributing to a more reliable and enjoyable shooting experience.

Whether you’re building a new AR-15 or upgrading an existing one, paying close attention to the feed ramps machined into the upper receiver can make a significant difference in the firearm’s performance. A reliable AR-15 is a safe AR-15, and the feed ramps play a vital role in achieving that reliability. Don’t overlook this crucial component when making decisions about your AR-15 build or upgrade.

[See also: AR-15 Upper Receiver Buying Guide]

[See also: Troubleshooting AR-15 Feeding Issues]

[See also: Best AR-15 Ammunition for Reliability]