The Definitive Guide: What Temperature to Run an Ultrasonic Cleaner Using Mineral Spirits

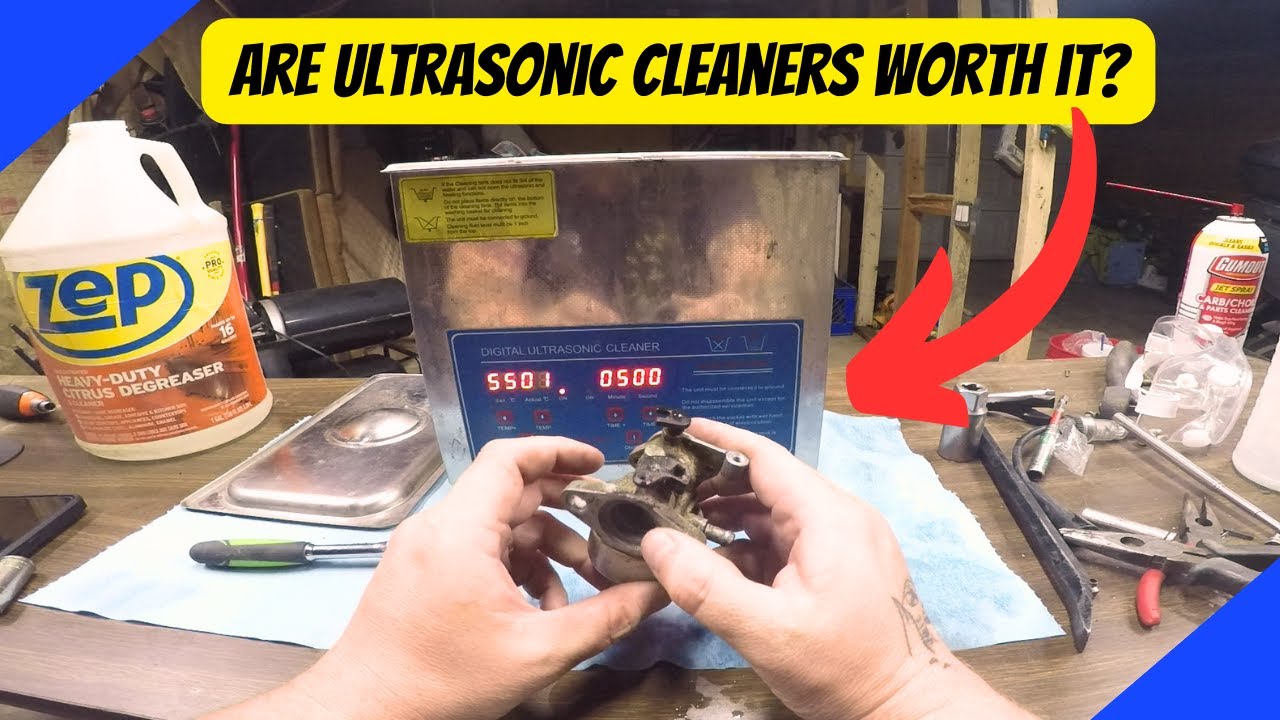

Ultrasonic cleaners have become indispensable tools across various industries, from automotive repair to jewelry cleaning. Their ability to remove contaminants from intricate parts quickly and efficiently is unmatched. However, the effectiveness and safety of an ultrasonic cleaner depend significantly on several factors, including the cleaning solution used and, crucially, the operating temperature. When using mineral spirits as the cleaning agent, understanding the optimal temperature range is paramount. This comprehensive guide delves into the nuances of temperature control when running an ultrasonic cleaner with mineral spirits, ensuring both effective cleaning and safe operation.

Understanding Mineral Spirits and Ultrasonic Cleaning

Before diving into the specifics of temperature, it’s essential to understand the properties of mineral spirits and their interaction with ultrasonic cleaners. Mineral spirits, also known as white spirits or Stoddard solvent, are petroleum-derived solvents commonly used for cleaning and degreasing. They are effective at dissolving oils, grease, waxes, and other organic contaminants. Their relatively low cost and availability make them a popular choice for many cleaning applications. However, mineral spirits are flammable and can release harmful vapors, making safety considerations critical.

Ultrasonic cleaners work by generating high-frequency sound waves in a liquid medium, creating microscopic bubbles that implode – a process known as cavitation. These imploding bubbles dislodge contaminants from the surfaces of immersed objects. The combination of mineral spirits and ultrasonic cleaning can be highly effective, but it also presents unique challenges related to temperature control.

The Importance of Temperature Control

Temperature plays a pivotal role in the ultrasonic cleaning process when using mineral spirits. Too low a temperature may reduce the effectiveness of the solvent, while too high a temperature can increase the risk of fire and the release of hazardous vapors. Here’s a breakdown of why temperature control is so important:

- Solvent Efficiency: Mineral spirits work best within a specific temperature range. Higher temperatures can increase the solvent’s ability to dissolve contaminants, but only to a certain point. Beyond that, the risk outweighs the benefits.

- Vapor Pressure: The vapor pressure of mineral spirits increases with temperature. This means that more vapors are released into the air at higher temperatures, increasing the risk of inhalation and fire.

- Cavitation Intensity: Temperature can affect the intensity of cavitation in the ultrasonic cleaner. While higher temperatures may initially increase cavitation, excessively high temperatures can dampen the effect, reducing cleaning efficiency.

- Material Compatibility: The temperature can impact the compatibility of mineral spirits with the materials being cleaned. Some materials may be damaged or corroded at elevated temperatures.

Optimal Temperature Range for Ultrasonic Cleaning with Mineral Spirits

So, what is the ideal temperature for running an ultrasonic cleaner with mineral spirits? The consensus among experts is that the temperature should be kept below the flash point of the mineral spirits. The flash point is the lowest temperature at which a liquid can form an ignitable mixture in air. Exceeding this temperature can create a significant fire hazard.

Typically, mineral spirits have a flash point between 104°F (40°C) and 140°F (60°C). Therefore, it is generally recommended to keep the temperature of the mineral spirits in an ultrasonic cleaner below 100°F (38°C). This provides a safety margin and reduces the risk of fire.

While keeping the temperature below 100°F (38°C) is crucial for safety, the optimal temperature for cleaning efficacy may vary depending on the specific mineral spirits used and the type of contaminants being removed. Experimentation within the safe range may be necessary to determine the best temperature for your application.

Factors Influencing Temperature Settings

Several factors can influence the ideal temperature setting for your ultrasonic cleaner when using mineral spirits:

- Type of Mineral Spirits: Different formulations of mineral spirits have varying flash points and cleaning properties. Always consult the manufacturer’s safety data sheet (SDS) to determine the specific flash point of the mineral spirits you are using.

- Contaminant Type: The type of contaminants being removed can influence the optimal temperature. Heavier oils and greases may require slightly higher temperatures for effective removal, while lighter contaminants may be effectively removed at lower temperatures.

- Part Material: The material of the parts being cleaned can also influence the temperature setting. Some materials are more sensitive to heat than others and may require lower temperatures to prevent damage.

- Ultrasonic Cleaner Power: The power of the ultrasonic cleaner can affect the temperature of the cleaning solution. Higher power settings can generate more heat, potentially requiring lower temperature settings.

- Ambient Temperature: The ambient temperature of the environment can also affect the temperature of the cleaning solution. In warmer environments, the solution may heat up more quickly, requiring lower temperature settings.

Safety Precautions When Using Mineral Spirits in Ultrasonic Cleaners

Safety should always be the top priority when using mineral spirits in an ultrasonic cleaner. Here are some essential safety precautions to follow:

- Ventilation: Always operate the ultrasonic cleaner in a well-ventilated area to prevent the buildup of harmful vapors. Consider using a fume hood to extract vapors away from the operator.

- Flammable Materials: Keep flammable materials away from the ultrasonic cleaner to prevent fires. This includes paper, cloth, and other solvents.

- Grounding: Ensure that the ultrasonic cleaner is properly grounded to prevent static electricity buildup, which can ignite flammable vapors.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves and eye protection, to protect yourself from contact with mineral spirits.

- Fire Extinguisher: Keep a fire extinguisher readily available in case of a fire. Make sure the extinguisher is rated for use with flammable liquids.

- Temperature Monitoring: Use a reliable thermometer to monitor the temperature of the mineral spirits during operation. Do not rely solely on the ultrasonic cleaner’s temperature control system.

- Avoid Overheating: Never allow the mineral spirits to overheat. If the temperature approaches the flash point, immediately turn off the ultrasonic cleaner and allow the solution to cool.

- Proper Disposal: Dispose of used mineral spirits properly in accordance with local regulations. Do not pour mineral spirits down the drain or into the environment.

Step-by-Step Guide to Setting the Temperature

Here’s a step-by-step guide to setting the temperature of your ultrasonic cleaner when using mineral spirits:

- Consult the SDS: Refer to the Safety Data Sheet (SDS) for the specific mineral spirits you are using to determine its flash point.

- Determine Target Temperature: Choose a target temperature well below the flash point, ideally below 100°F (38°C).

- Fill the Tank: Fill the ultrasonic cleaner tank with the appropriate amount of mineral spirits, following the manufacturer’s instructions.

- Set the Temperature: Set the temperature control on the ultrasonic cleaner to your target temperature.

- Monitor the Temperature: Use a reliable thermometer to monitor the temperature of the mineral spirits as the ultrasonic cleaner operates.

- Adjust as Needed: If the temperature exceeds your target temperature, reduce the power setting or add cooler mineral spirits to the tank.

- Maintain Consistent Temperature: Throughout the cleaning process, continuously monitor the temperature and adjust as needed to maintain a consistent temperature below the flash point.

Alternative Cleaning Solutions

If you are concerned about the safety risks associated with using mineral spirits, consider using alternative cleaning solutions that are less flammable and have lower vapor pressures. Some popular alternatives include:

- Aqueous Cleaners: Water-based cleaners are generally safer than solvent-based cleaners and can be effective for removing many types of contaminants.

- Citrus-Based Solvents: These solvents are derived from citrus fruits and are biodegradable and less toxic than mineral spirits.

- Synthetic Solvents: A variety of synthetic solvents are available that offer a balance of cleaning power and safety.

When choosing an alternative cleaning solution, consider the type of contaminants being removed, the material of the parts being cleaned, and the environmental impact of the solution. [See also: Best Ultrasonic Cleaning Solutions for Automotive Parts]

Troubleshooting Temperature Issues

Sometimes, you may encounter issues with temperature control in your ultrasonic cleaner. Here are some common problems and their solutions:

- Temperature Too High: If the temperature is consistently too high, check the power setting, ambient temperature, and cooling system (if equipped). Reduce the power setting, improve ventilation, or add a cooling system to the ultrasonic cleaner.

- Temperature Too Low: If the temperature is consistently too low, check the heating element and temperature sensor. Replace any faulty components.

- Temperature Fluctuations: If the temperature fluctuates erratically, check the temperature control system and the level of mineral spirits in the tank. Ensure that the temperature control system is functioning properly and that the mineral spirits are at the correct level.

Conclusion

Using mineral spirits in an ultrasonic cleaner can be an effective way to remove contaminants from various parts. However, it’s crucial to understand and control the temperature to ensure both effective cleaning and safe operation. By following the guidelines outlined in this comprehensive guide, you can minimize the risks associated with using mineral spirits and maximize the benefits of ultrasonic cleaning. Remember to always prioritize safety, consult the SDS for your specific mineral spirits, and experiment within the safe temperature range to find the optimal settings for your application. Understanding what temperature to run an ultrasonic cleaner using mineral spirits is key for effective and safe operation. When used correctly, mineral spirits and ultrasonic cleaning can be a powerful combination for a variety of cleaning needs. The correct temperature to run an ultrasonic cleaner using mineral spirits will provide the best results. The temperature you choose to run an ultrasonic cleaner using mineral spirits should be appropriate for the materials being cleaned. Always check the temperature when you run an ultrasonic cleaner using mineral spirits. Always be cautious about what temperature to run an ultrasonic cleaner using mineral spirits. When you run an ultrasonic cleaner using mineral spirits, be sure to read the safety data sheet. The best temperature to run an ultrasonic cleaner using mineral spirits is generally below 100°F (38°C). Safety is paramount when considering what temperature to run an ultrasonic cleaner using mineral spirits.